VT336t Industrial Monitoring Unit

Description

“VT336t / Industrial Monitoring Unit” is a monitoring and control unit specially designed for DIN rail installations, industrial racks, and electrical installations.

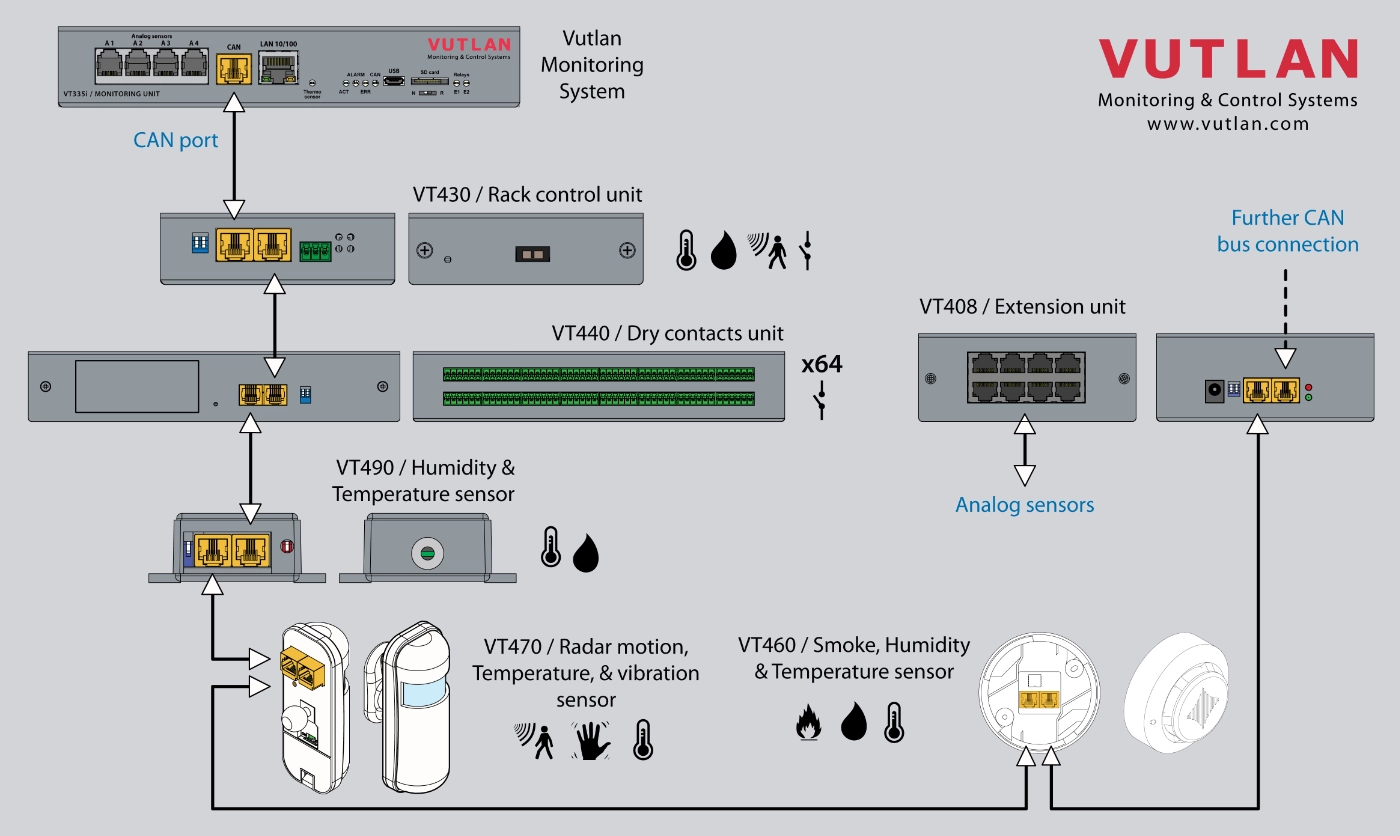

The system is used for environmental monitoring of up to 100 physical sensors (e.g. temperature, humidity, voltage, leakage, smoke, airflow, and others).

It is an I/O controller for managing devices and power (e.g. power, door, fans, generator, control panels, UPS, circuit breakers, and alarms).

It can use up to 700 different elements - notifications, triggers, timers, logic schemes, events, sensors, dry contact inputs/outputs, and others.

Hardware specifications

- Grad A

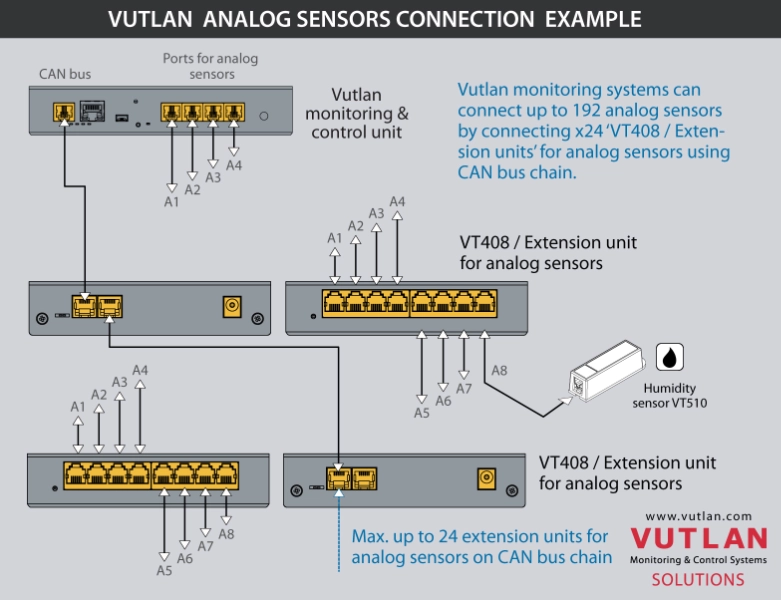

- VT408 analog sensor extension unit adds more ports

- Plug & Play

- 5 level thresholds

- Hysteresis for alert delay if the sensor value jumps to fast

- Linear formula for sensor value adjustments

- Math element for calculating your own formulas

- Graphs, multi-graphs

- Ethernet 10/100 Base-T port, provides an Ethernet connection

- VT740 LTE modem ordered separately

- SMS notifications

- Ethernet, network reservation

- Purchased separately

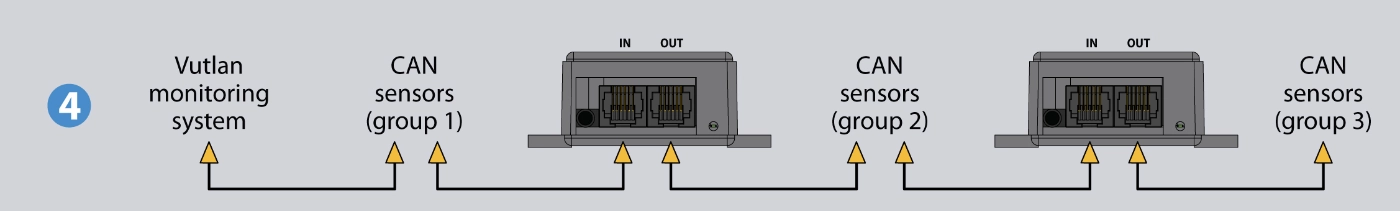

- Connect digital CAN sensors in a daisy chain

- Connect CAN extensions

- Restart button

- Factory reset

- N-R switch

- Activity, Error, Alarm

- x2 12V relays

- x2 NC-NO-COM relays

- Receive voltage free signals from devices and sensors

- E.g. door sensor, window sensor, UPS, diesel generators, circuit breakers, alarm system, control panels, and other industrial equipment.

- Connect KMS-30 access sensor

- Send voltage signals

- E.g. UPS, diesel generators, circuit breakers, alarm system, control panels, and other industrial equipment.

- 12V DC 2A connector

- 12V DC 2A terminal, 3P, pitch 3.81

- 24-48V DC, 2P, 5.08mm pitch

- Control VT103 alarm beacon

- Control VT105 strobe light

- Control VT11 relay contact switch

- Control other 12V DC devices

- Install VT485m Modbus RTU extension

- Purchased separately

- Temperature

- Voltage sensors for power supply inputs

- Chassis grounding

Use cases

The VT336t is a versatile monitoring system that offers various use cases across different applications. Here are some of the main use cases:

- Data Center Monitoring: The VT336t is ideal for monitoring environmental conditions in data centers, such as temperature, humidity, and power consumption. It can help ensure optimal conditions for equipment, preventing overheating and failures.

- Facility Management: In commercial buildings, the VT336t can be used to monitor and control HVAC systems, lighting, and security. This helps maintain energy efficiency and comfort for occupants while providing alerts for maintenance needs.

- Industrial Automation: The VT336t can integrate with various sensors and devices to monitor processes in manufacturing plants. It can track machinery performance, environmental conditions, and safety measures, allowing for real-time data analysis and decision-making.

- Remote Site Monitoring: For remote locations, such as oil rigs or telecommunications towers, the VT336t can monitor equipment status and environmental factors. This capability allows operators to receive alerts and manage assets effectively from a distance.

- Energy Management: The system can track power usage in real-time, helping businesses analyze energy consumption patterns. This data can be used to implement energy-saving strategies and reduce operational costs.

- Alarm and Notification Systems: The VT336t can be configured to trigger alarms based on specific thresholds for various parameters, such as smoke detection or temperature spikes. This is crucial for safety in environments like warehouses and factories.

- Research and Development: In laboratories or testing facilities, the VT336t can be used to monitor experimental conditions, ensuring precise data collection for research projects.

- IoT Integration: The VT336t supports integration with IoT devices, allowing for smart building applications and enhanced data analytics. This feature enables advanced automation and control strategies.

Extensions

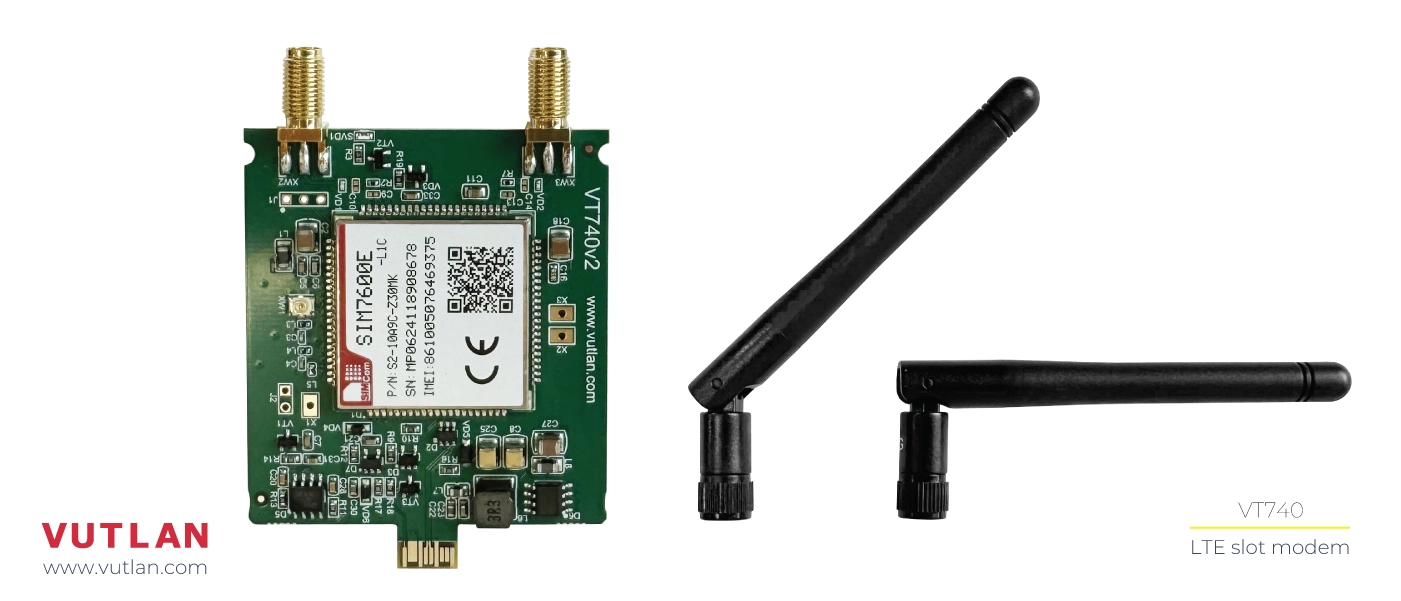

VT7670 LTE slot modem

Allows to receive and send SMS notifications (2G, 3G). Provides Ethernet reservation over LTE (4G).

VT485m Modbus extension

Allows to monitor up to 32 Modbus RTU devices/meters/sensors.

Advanced protocols

Vutlan supports most popular communication protocols & adding more...

SNMP v1, v2c, v3

Simple Network Protocol for connecting multiple Vutlan units to a single DCIM, NMS, and Infrastructure monitoring software.

+

Modbus RTU,

Modbus TCP

Modbus serial communication protocol designed for industrial automation systems, and industrial meters.

+

and other...

DHCP, HTTP, HTTPS, SMTP, FTP, Syslog, TLS, DynDNS, RADIUS, SSL, NTP, OpenVPN

Pushing limits

The most powerful monitoring and control systems in the world!

OS Linux

v.6.2

Processors

600 MHz, 2 Cores

Maximum sensors

100 physical sensors

Maximum elements

700 virtual elements

Embedded Web Interface

All Vutlan monitoring units come with a built-in multi-language Web Interface for monitoring and control of the device. Here you can configure notifications & alerts, logic schemes, user access permissions, sensors, and elements. You can also inspect sensor graphs, logs, or view cameras.

Add more analog sensors using VT408 or VT408DIN

'VT408 Sensor extension unit' and 'VT408DIN Sensor extension unit" increase the number of analog sensors connected to any Vutlan monitoring unit. Each VT408 unit adds 8 analog sensors. Multiple VT408 units can be connected using a daisy CAN chain. Sensors connected to the extension unit appear in the system automatically.

-01.webp)

Add more dry contact inputs using VT440

'VT440 / Dry contacts extension unit' increases the number of dry contact input terminals connected to any Vutlan monitoring unit.

Each VT440 unit adds x32 terminals. Each VT440 unit + VT32 extension adds x64 terminals.

Multiple VT440 units can be connected using a daisy CAN chain.

Vutlan web interface offers a separate dry contact inputs panel for monitoring, control and configuration.

Connecting CAN sensors

You can connect up to x32 CAN units in a CAN bus chain.

E.g. Each VT408 unit in a CAN bus chain adds 8 analog sensors.

E.g. Each VT440 unit adds x32 or x64 dry contact inputs to the system.

The additional power supply CAN12V-1A is needed only if the number of sensors in a CAN bus chain is more than 12 sensors. Supplies power for each additional group of 12 sensors.

Centralized Infrastructure Management Software using SNMP protocol

No matter how complex your IT infrastructure is, you can manage all assets using DCIM SNMP software, infrastructure management software.

Vutlan supports SNMP v1, SNMP v2c, SNMP v3. Hence the data from Vutlan monitoring units can be monitored from any SNMP managemnt software package.

Software specifications

- Full monitoring and control over IP

- Day / night cycles

- Manual season time setup

- Multi language web interface

- Floor map plan with layers and vectors

- System & group trees

- Logic schemes (IF, THEN, OR, AND events)

- No programming skills needed

- One time or repeated events

- Control equipment

- Send notifications

- Event triggers

- Group events

- Duplicator license is purchased separately

- For management of multiple devices

- Upload configuration and firmware

- USB camera (JPEG stream notifications)

- IP cameras (only view)

- Monitoring: modules, sensors, groups, map, USB web-cam & etc.

- CAN bus configuration

- Users DB

- Access keys DB

- Date and time configurations

- Network settings

- HTTP Server settings

- Logging settings

- Radius settings

- SNMP settings

- DynDNS

- Settings of update

- Settings of backup

- No SSH

- SSL cerrtificate

- OpenVPN client & server

- Routing

- NTP server

- Dynamic DNS

- Radius server

- Sensor graphs