Vutlan offers leak cable sensors, spot leakage detection probes and other solutions.

Leak detection

Water or liquid damage caused by leaks can cause serious damage over time if not prevented in time and can cost businesses millions of dollars worth of damage. Water leaks are the most common reasons for data loss, equipment failure or facility damage. The loss of critical data can be devastating to a business, and no amount of money can bring it back once destroyed.

Vutlan leakage detection solutions and their advantages

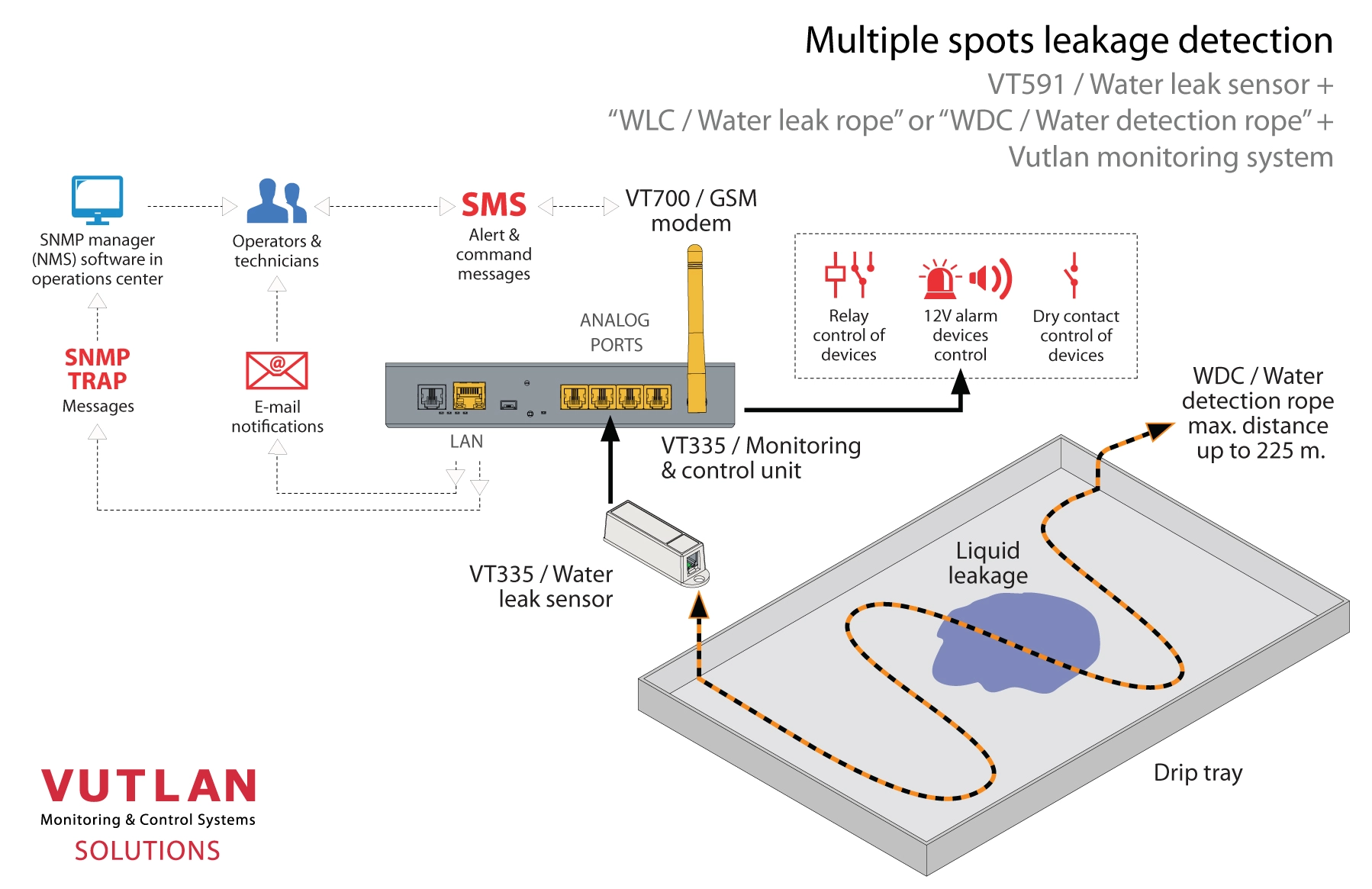

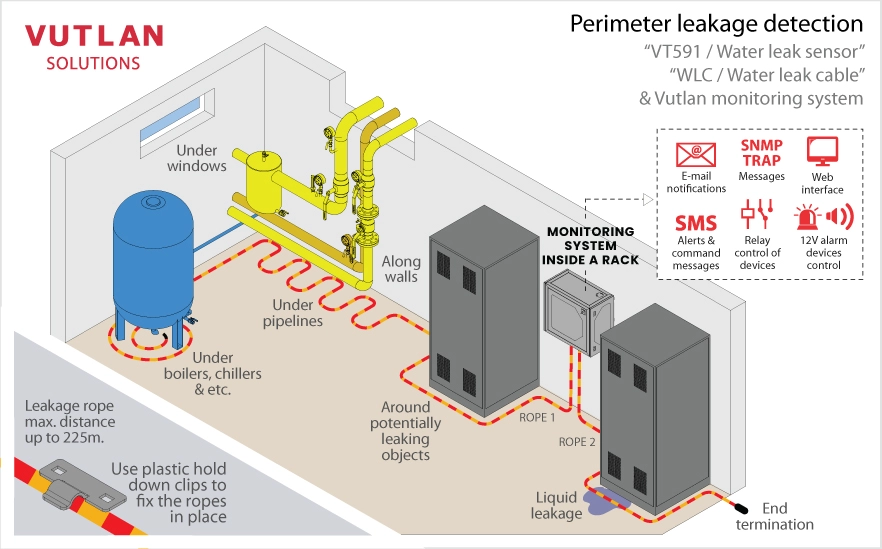

Vutlan offers a very powerful, and potentially money-saving water leak detection system offering: leak detection cable sensors; water leak spot sensors; monitoring systems with built-in notifications (SNMP, E-mail, SMS, Syslog) for notifying the personnel; 12V control of alarm beacons and strobe lights; relay and dry contact outputs for control of devices.

Vutlan water leakage detection system advantages include:

- Leak cable sensors cover the whole area

- Spot leak sensor for single point

- A robust web interface that gives the ability to independently track many leaks at once, with local, networked or remote alarms and diagnostics.

- Support of SNMP for integration to building management systems, E-mails, SMS, and Syslogs.

- Configuration options that automatically shut off equipment or pumps/valves where appropriate (e.g. using dry contact outputs or relays).

- Ability to monitor up to 100-150 leak sensors independently of each other.

- Very affordable prices

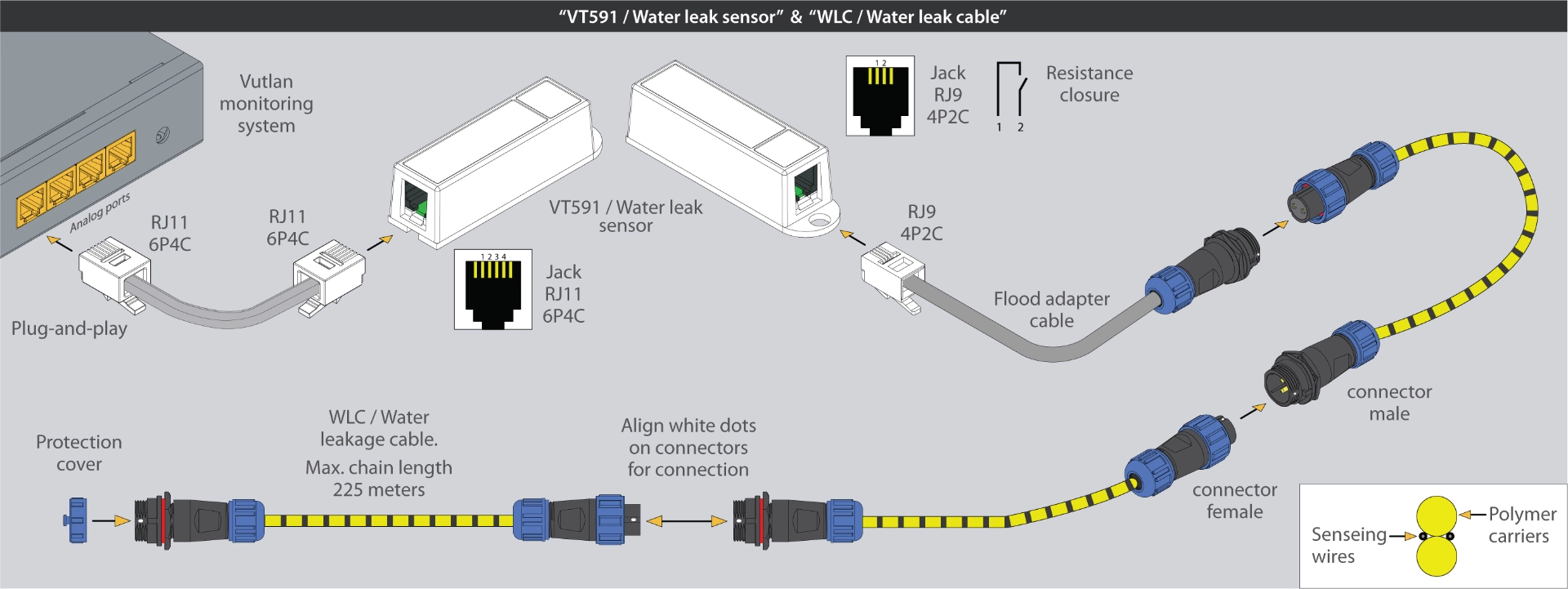

VT591 / Water leak sensor

WLC / Water leakage cable

"VT591 requires "WLC / Water leakage cable". The whole area can be effectively monitored by placing the leaked cable near or along with possible flood sources.

- The sensor reacts to just a few drops of liquid on WLC cable.

- Can detect the emergence of moisture.

- The cable is flexible and easy to install.

- VT591 is an analog plug-and-play sensor.

- After the flooding, the leak detection cable can be dried and reused.

- The sensor does not produce false alarm signals when bent or twisted.

- Detectable liquids include clean, polluted, and distilled water; acids; alkalis; alcohols, and other electrically conductive liquids.

- Different length of leak detection cavles availabe for order.

- Possibility to extend the WLC leakage cables by connecting them to each other.

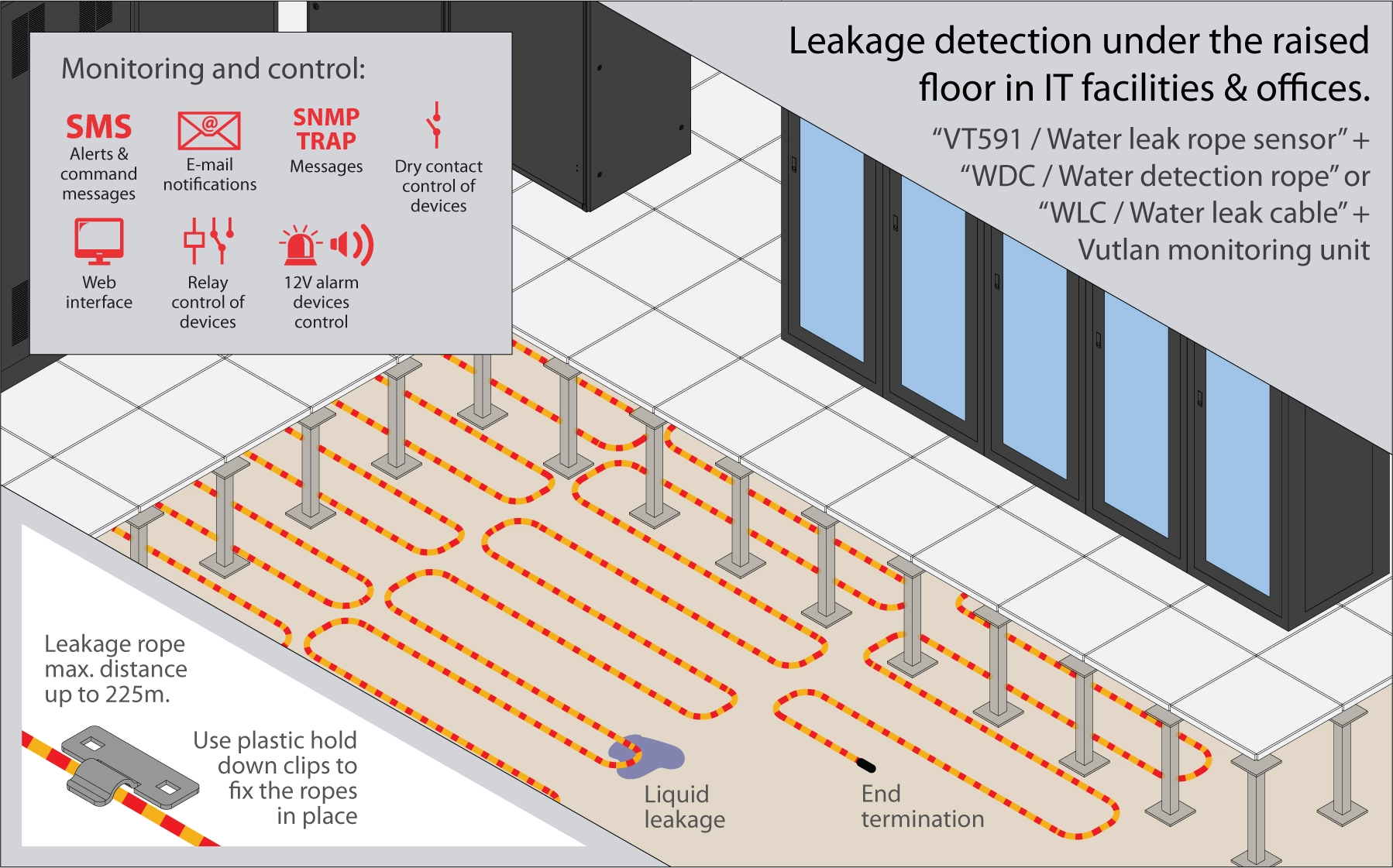

Example: Leakage detection under raised floors

Monitoring the status of concealed cables and wires beneath floor panels may be difficult. Cables may be soaking in water for a long period before anyone notices. Vutlan WLC cable can be installed the whole area under the raised floors.

- Below raised floors

- Cover the whole area

- Lay down multiple cables per area for pinning down the leakage origin.

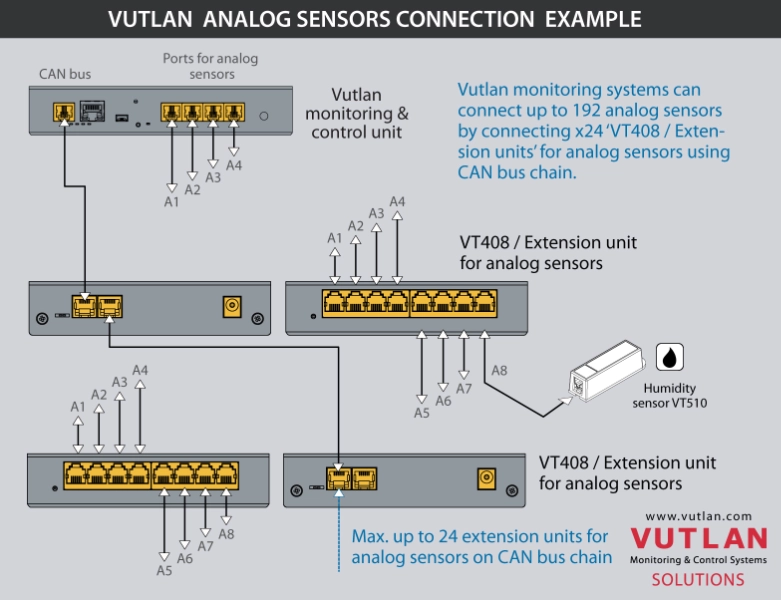

Add more analog sensors using VT408

'VT408 / Sensor extension unit' increases the number of analog sensors connected to any Vutlan monitoring unit. Each VT408 unit adds 8 analog sensors. Multiple VT408 units can be connected using a daisy CAN chain. Sensors connected to the extension unit appear in the system automatically.

VT593 / Spot leak sensor

The sensor detects water by increasing capacitance on two metal poles. The detector is encapsulated in plastic housing. Due to the low applied voltages and the applied leakage detection principle, it does not rust over time.

Scalability

Add more analog sensors using VT408 or VT408DIN

'VT408 Sensor extension unit' and 'VT408DIN Sensor extension unit" increase the number of analog sensors connected to any Vutlan monitoring unit. Each VT408 unit adds 8 analog sensors. Multiple VT408 units can be connected using a daisy CAN chain. Sensors connected to the extension unit appear in the system automatically.

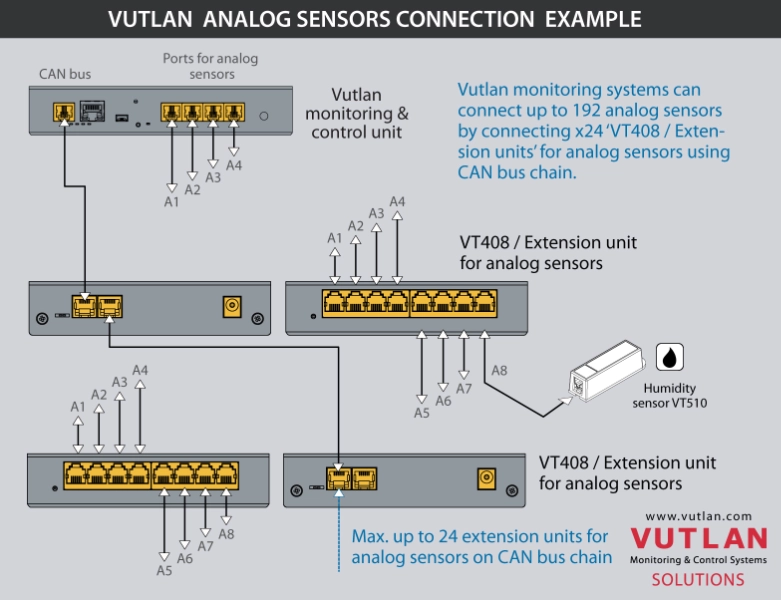

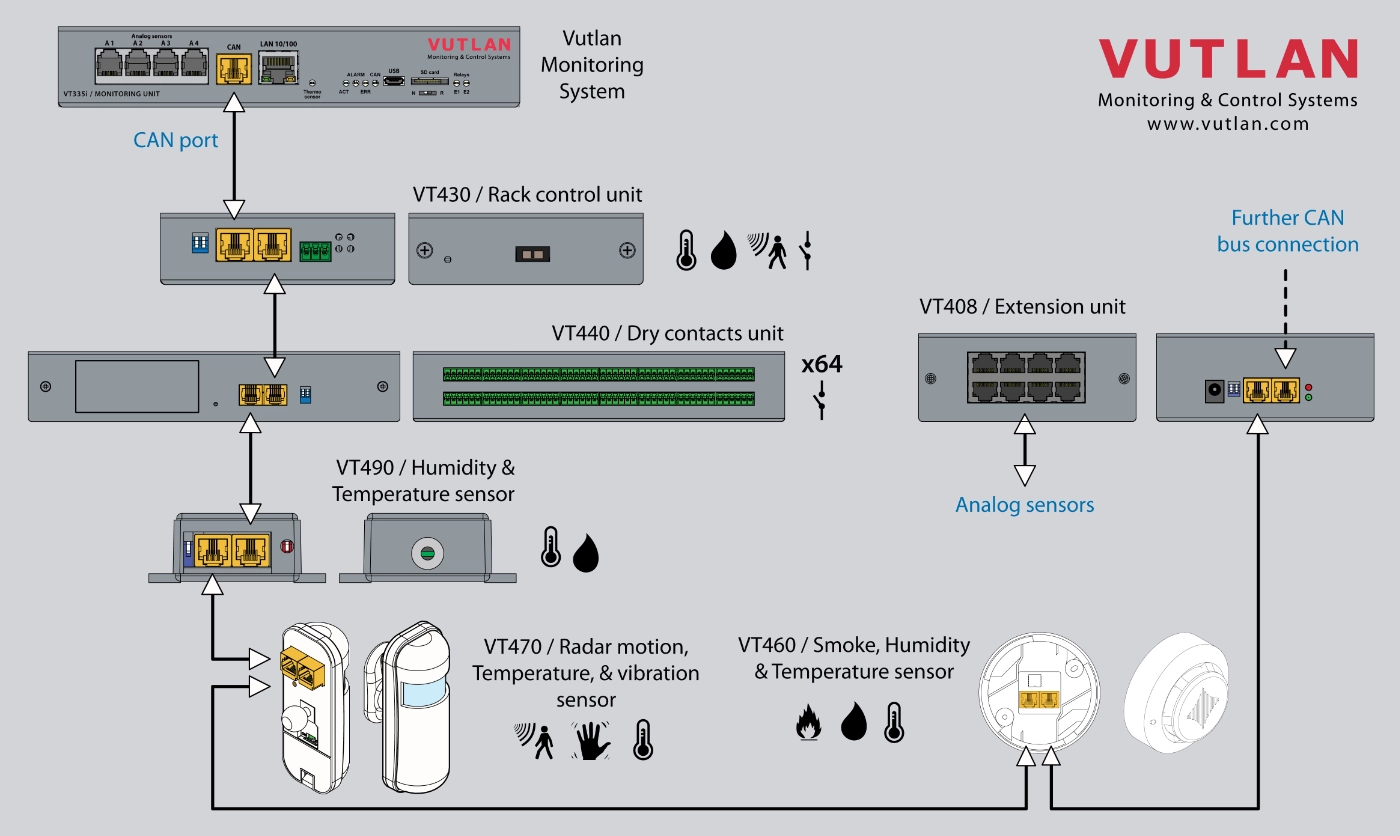

Connecting CAN sensors

You can connect up to x32 CAN units in a CAN bus chain.

E.g. Each VT408 unit in a CAN bus chain adds 8 analog sensors.

E.g. Each VT440 unit adds x32 or x64 dry contact inputs to the system.

The additional power supply CAN12V-1A is needed only if the number of sensors in a CAN bus chain is more than 12 sensors. Supplies power for each additional group of 12 sensors.

Embedded Web Interface

All Vutlan monitoring units come with a built-in multi-language Web Interface for monitoring and control of the device. Here you can configure notifications & alerts, logic schemes, user access permissions, sensors, and elements. You can also inspect sensor graphs, logs, or view cameras.

Systems with analog ports:

To read data from the analog sensors, you need Vutlan monitoring and control system. All the following monitoring & control systems have a different amount of analog ports.