VT450 Pressure, humidity & temperature sensor

Price:

€137.76

Tax included

Description

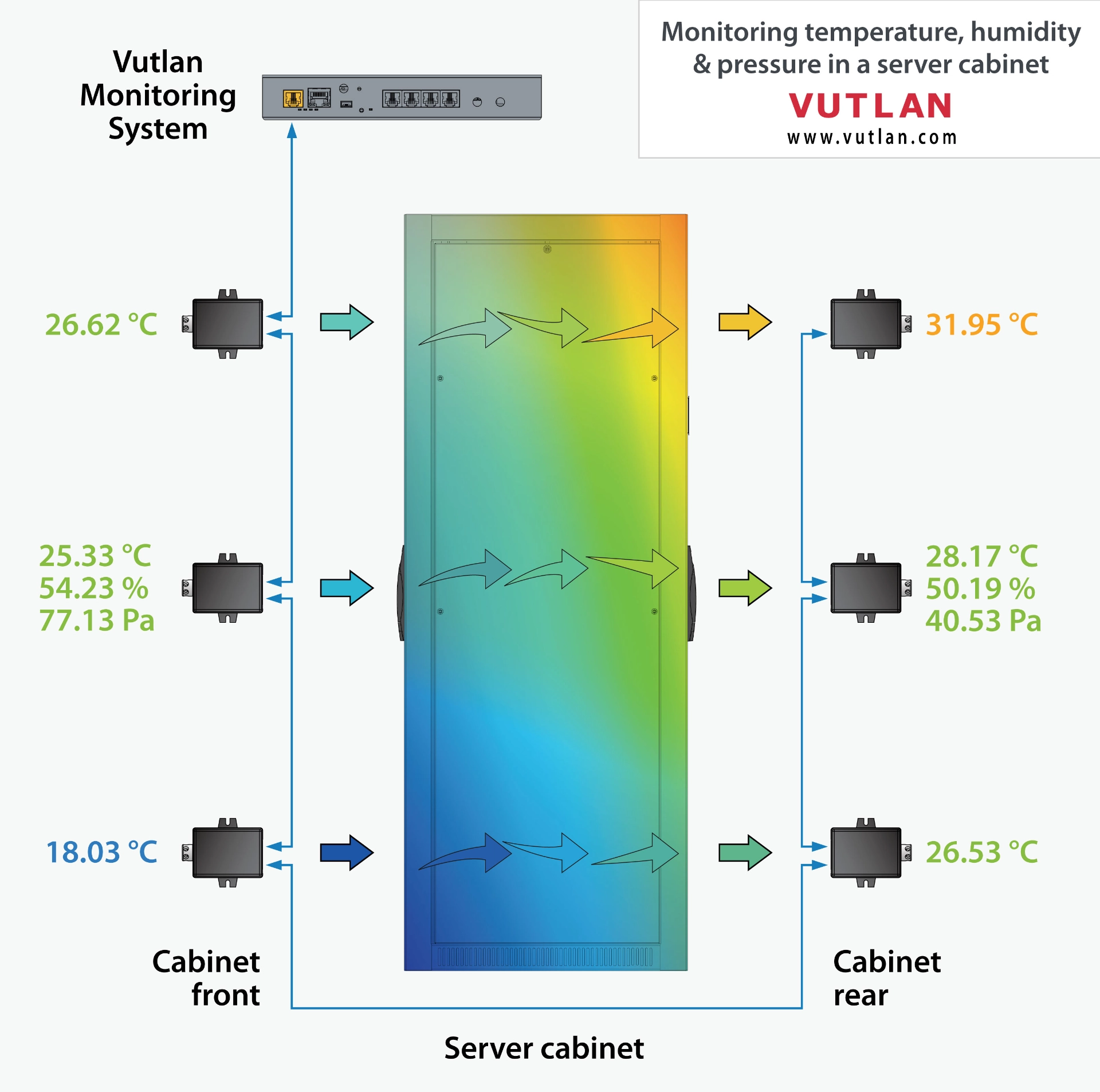

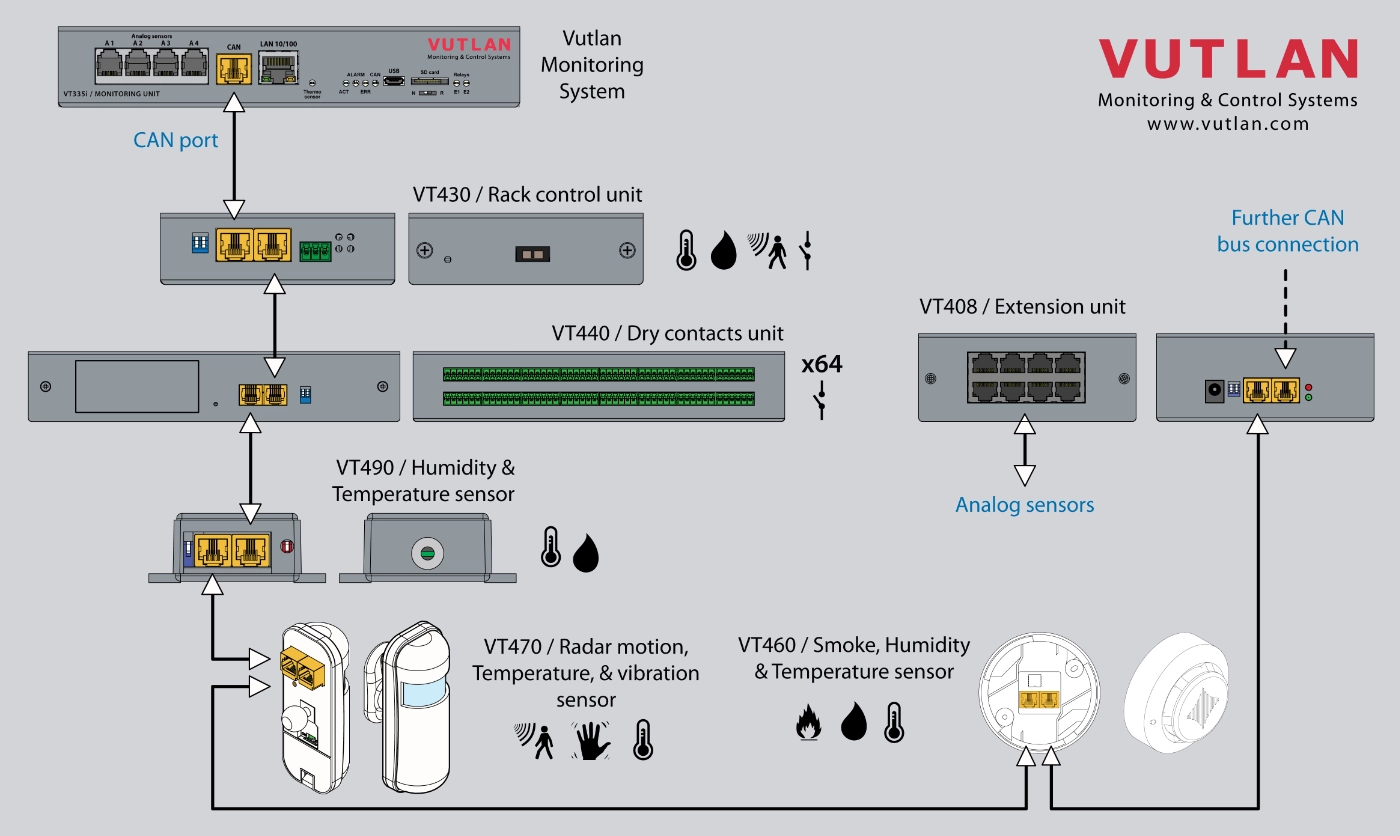

The VT450 Triple sensor is a high-quality pressure, humidity and temperature sensor. By connecting VT450 in a CAN daisy chain you can measure parameters in each location of a room or a server rack.

The Dew point is easily calculated using the temperature and humidity parameters of VT450 sensor inside the Vutlan web interface.

CAN devices and sensors can be chained together. Up to 10-32 CAN devices can be connected in a chain.

RH accuracy is ± 3%, temperature accuracy is ± 1°C, pressure accuracy is ±1.5Pa/K.

Use cases

The flexibility of the VT450 sensor is critical, allowing it to be adapted to any specific environmental conditions.

- Data centers: Provide precise environmental control by monitoring temperature, humidity and pressure.

- Warehouses: Used to monitor and maintain ideal environmental conditions.

Specifications

Detects:

Pressure, humidity and temperature

Device type:

CAN bus device

Network Interface:

CAN open

Inputs/Outputs:

Yes, a daisy chain is possible for all CAN sensors.

Pressure RMS noise:

0.2Pa (equivalent to 1.7cm)

Pressure error:

±0.25% (equivalent to 1m at 400m height change)

Pressure from °C:

±1.5Pa/K (equivalent to ±12.6cm at 1 °C temperature change)

RH accuracy:

± 3% RH (max)

Hysteresis:

≤2% RH

Response time:

1 s

Temperature:

1.5°C

Pressure range:

300 to 1100 hPa

Operating temperature:

-40° C to +85° C

Operating humidity:

0 to 95% RH

Power input:

12V DC, 1A (power supplied on a CAN bus chain)

Max. distance from the unit:

225m

Current consumption:

1 Watt

Dimensions:

68x47x26 mm

Mounting possibilities:

Desktop, Wall mount

LED indicators:

Red / Green (RUN/ERROR)

TR switch:

Activate if the unit is the last unit in a CAN bus chain.

Origin of goods:

Made in EU

HS Code:

9025 11 800

GTIN:

8588009886518

Warranty:

90 days

Sensor features

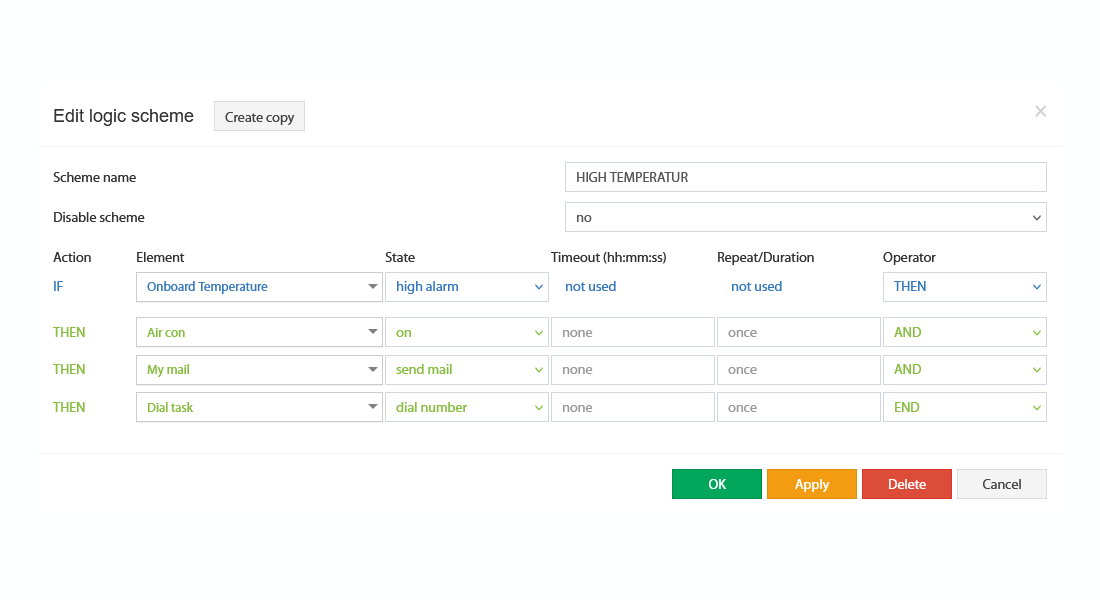

Logic schemes

Logical schemes are used to set automatic actions in response to events occurring in the system.

Dashboard view

The monitoring interface can be customized for each user.

There are widgets with multifunctional graphs and gauges.

Thresholds

Each sensor has 5 alarm thresholds for logical control and notifications.

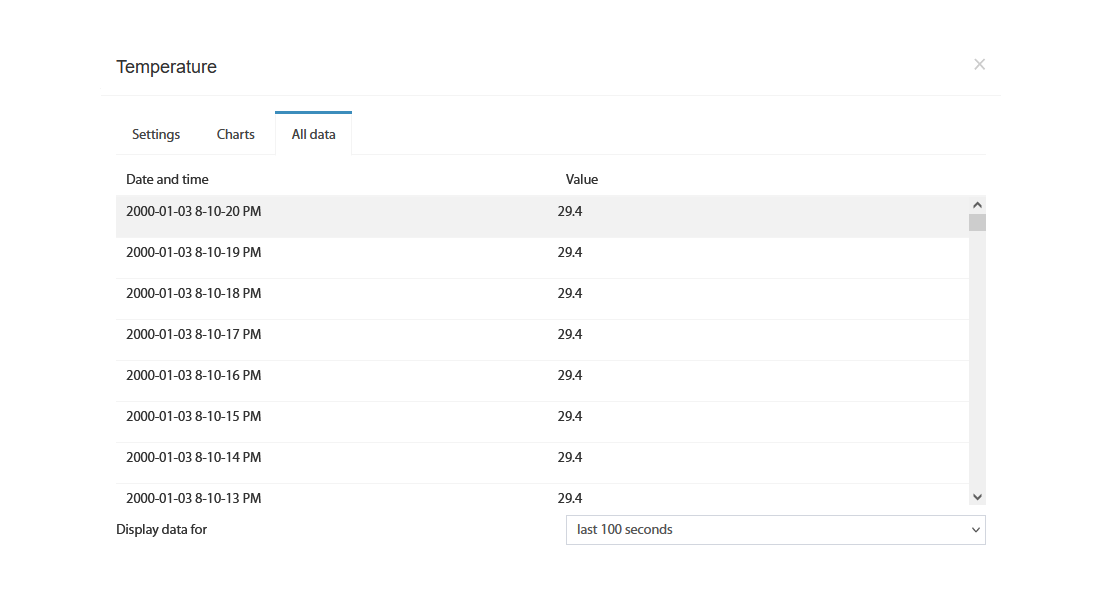

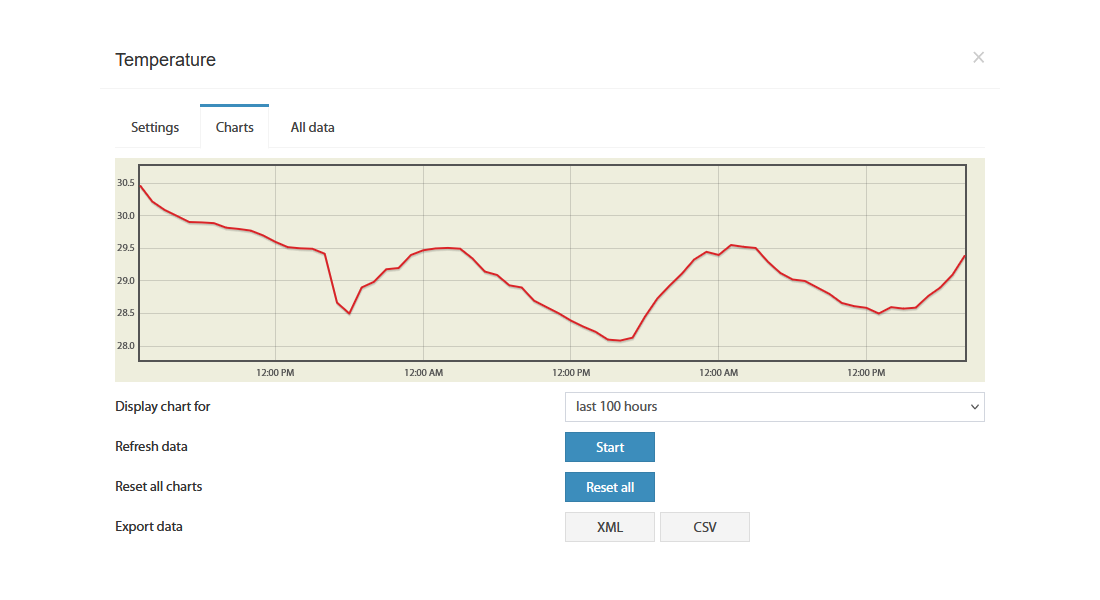

Graphs and Logging

Vutlan supports recording to SD card and USB stick.

Data from the entire system loaded with sensors is stored for up to 3 years.

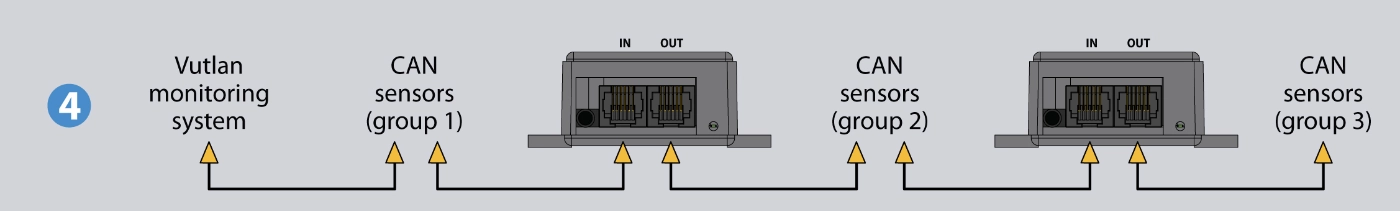

Connecting CAN sensors

You can connect multiple CAN devices to a CAN bus chain.

Each VT408 unit in the CAN bus chain adds 8 analog sensors. Each VT440 unit adds 32 or 64 dry contact inputs to the system.

An additional CAN12V-1A power supply is only required if the number of CAN devices in the CAN bus chain exceeds 12 pieces.

Systems with CAN ports:

To read data from the CAN sensors, you need a Vutlan monitoring device with one or two CAN ports.