New

VT407 AC current converter

Description

The HAT-100Q1 is a simple open-loop AC current transducer that measures AC currents in the range of 0-100A. It is designed for monitoring and controlling power consumption and is ideal for applications where precise AC current measurements are critical. The transducer detects the current and outputs an analog signal that can be processed by a monitoring system.

To transfer the measured AC current data, the VT407 AC converter is used. It is an analog plug-and-play device that connects to any available analog port (A1...A8) on a Vutlan monitoring unit. This allows for seamless integration of current monitoring into the broader Vutlan monitoring system, providing real-time data on current consumption and enabling the system to react to overcurrent situations or electrical failures.

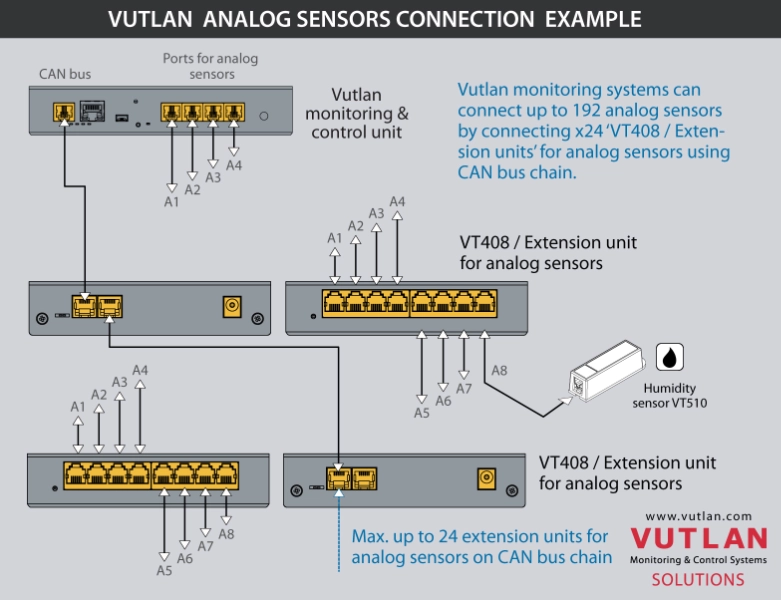

Additionally, the maximum number of VT407 converters connected to the system and the maximum length from the monitoring unit can be expanded using the VT408 / Sensor extension unit, offering scalability for larger monitoring setups or more complex infrastructures.

This combination is ideal for monitoring power usage in data centers, industrial environments, or telecommunications facilities, where reliable power monitoring is crucial for maintaining operational efficiency and safety.

Required Components

HAT-100Q1 AC current transducer

Simple open-loop AC current transducer HAT-100Q1 can measure AC currents in the range of 0-100A. Data can be transferred to the monitoring system using AC converter VT407.

Use cases

These use cases demonstrate the versatility of the HAT-100Q1 and VT407 for various industries, particularly where accurate AC current monitoring is crucial for maintaining operational safety, efficiency, and reliability.

- Real-time AC current monitoring: Ensuring that server racks and cooling systems are operating within the correct current limits to prevent overloads or electrical failures.

- Energy Usage Optimization: Tracking the power consumption of critical infrastructure to identify areas for reducing energy waste and improving overall efficiency.

- Motor Current Monitoring: Measuring the current drawn by industrial motors to detect potential issues like overcurrent, which could lead to motor failure or energy inefficiency.

- Equipment Health Monitoring: Providing insights into the health of electrical equipment by monitoring current fluctuations, allowing for predictive maintenance and avoiding unexpected downtime.

- Power Supply Monitoring: Monitoring the current flowing to telecommunications equipment to ensure that devices such as routers, switches, and backup power systems are receiving stable and reliable power.

- Backup Systems: Ensuring that AC power backup systems (like generators or UPS units) function properly during power outages by monitoring the current being drawn.

- Solar Inverters and Wind Turbines: Monitoring the AC current generated by renewable energy sources such as solar panels or wind turbines to ensure they are operating within safe limits and optimizing energy output.

- Grid Integration: Tracking the current flow from renewable systems into the main grid for efficient energy distribution and ensuring compliance with grid standards.

- HVAC System Monitoring: Ensuring that air conditioning, heating, and ventilation systems are running efficiently by measuring the current used by large fans, compressors, and other components in the system.

- Load Management: Preventing overloading of circuits by monitoring the power consumption of multiple HVAC units, particularly in large commercial buildings.

- Charging Current Monitoring: Tracking the AC current supplied to electric vehicles at charging stations to ensure proper and efficient charging, preventing damage to both the vehicle and the charging infrastructure.

- Fault Detection: Detecting abnormal current spikes or drops, which can indicate faults in the charging system or the vehicle, ensuring safety and reliability.

- Load Shedding: Monitoring the AC current to strategically reduce the load on electrical circuits during peak energy usage periods, preventing overloads and improving energy efficiency.

Specifications

Type of sensor:

Converter/adapter for AC current transducer

Used for:

Captures the data from AC current transducer and transfers the data to the Vutlan monitoring unit as an analog signal.

Output:

RJ-11 / RJ-12 6P4C

Inputs:

4P terminal, pitch 5.08mm:

GND, 0…+5V, -12V, +12V

Maximum distance:

50 meters from the monitoring unit or VT408 analog sensor extension

Operating temperature:

Min. -10° C - Max. 80° C

Operating humidity:

Min. 5% - Max. 95% (Non-Condensing)

Power input:

12V DC, 1A

Power consumption:

100 mW

Dimensions:

Size 68 × 47 x 26 mm

Mounting:

Desktop, Wall mount

Manufactured in:

Manufactured in the EU, Slovak Republic, Vutlan s.r.o.

HS Code:

9030 33 100

GTIN:

8588009886556

Previous

Next

Sensor features

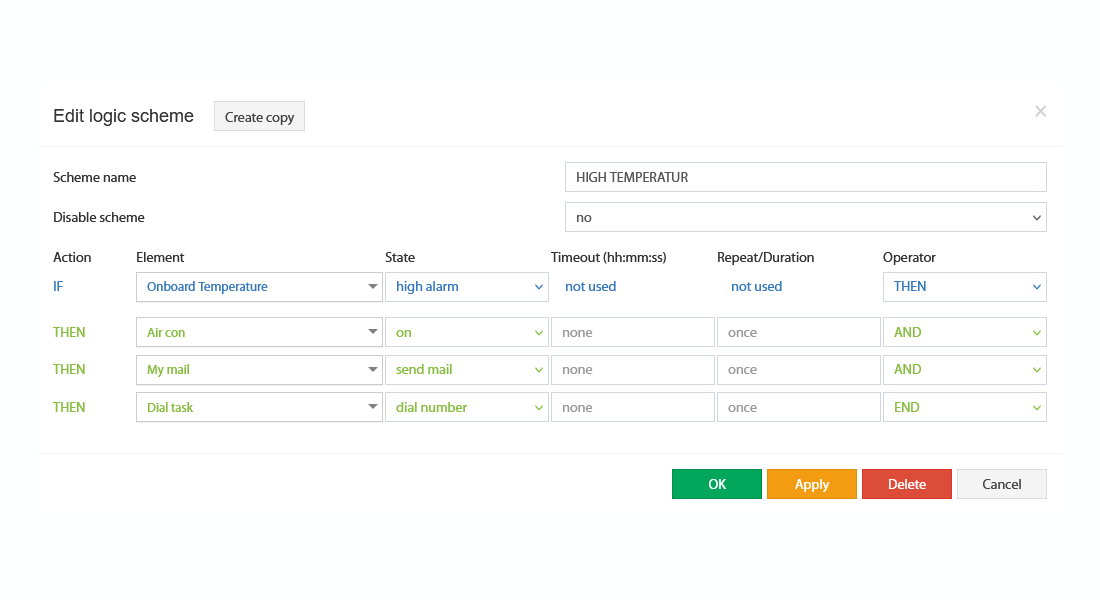

Logic schemes

Logic schemes are used to specify automatic actions to events that occur in the system.

Dashboard view

The system allows to customize the dashboard individually for each user and displays the most important information on it in a visual form.

Add widgets with multi graphs, gauge meters or knobs.

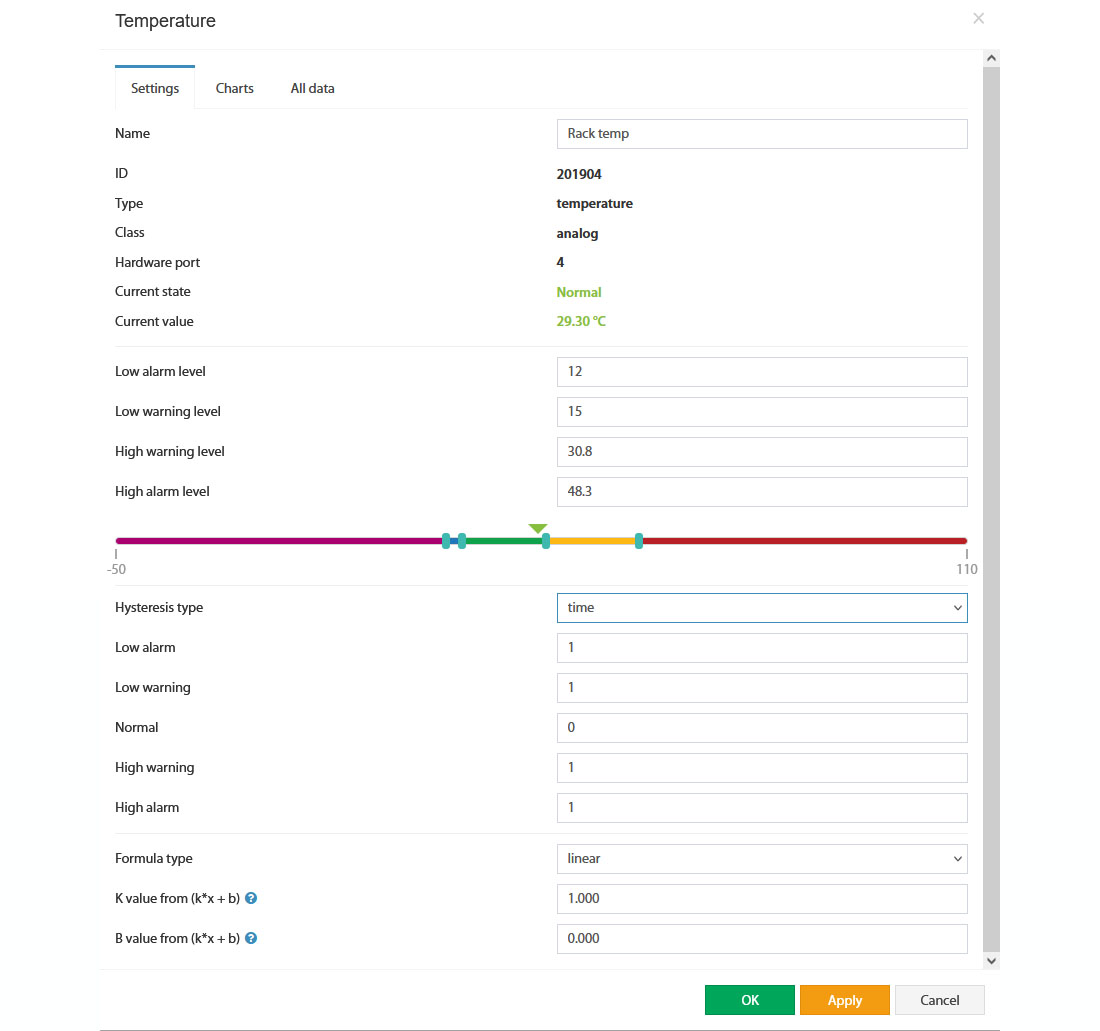

Thresholds

Each sensor has Low Alarm, Low Warning, Normal, High Warning, and High alarm threshold states for logic control & sending of notification.

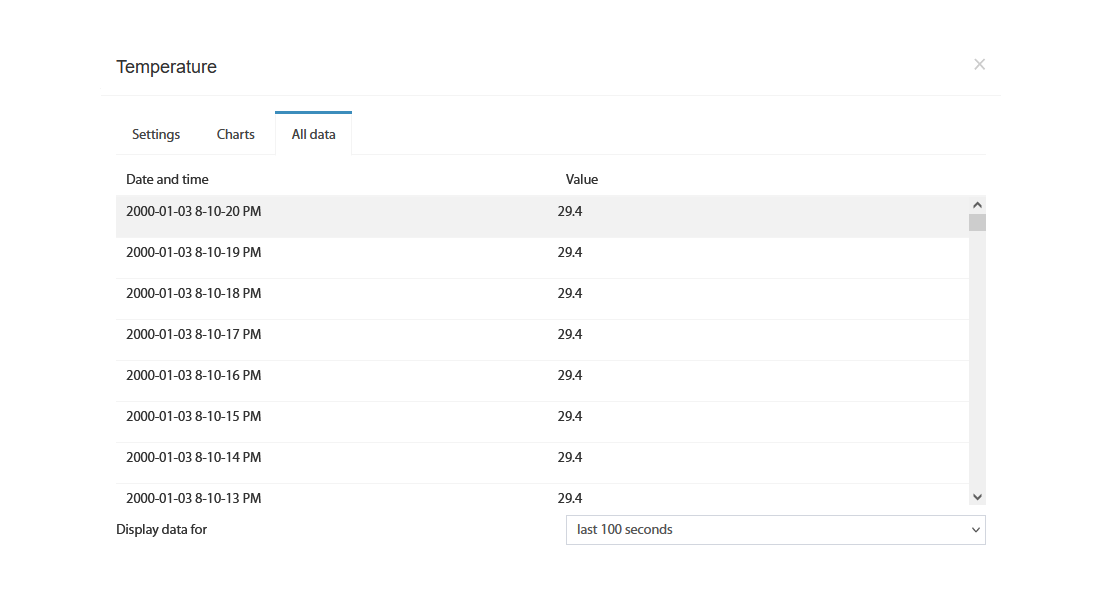

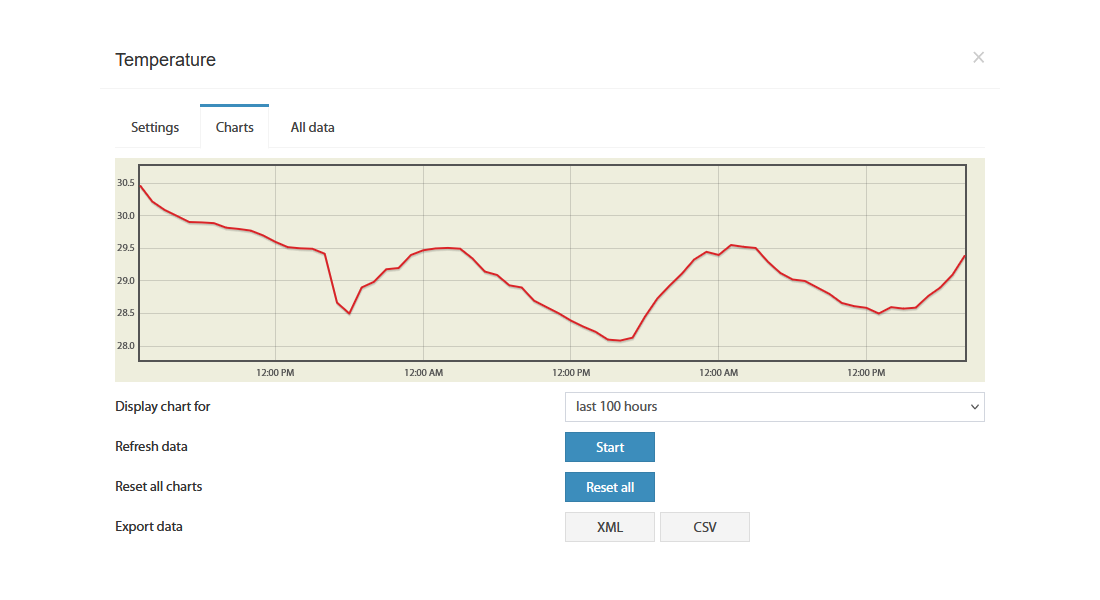

Graphs and Logging

Vutlan supports SD card logging up to 500 Gb. You can log a whole systems loaded with sensors for 3 years.

Previous

Next

Add more analog sensors using VT408 or VT408DIN

'VT408 Sensor extension unit' and 'VT408DIN Sensor extension unit" increase the number of analog sensors connected to any Vutlan monitoring unit. Each VT408 unit adds 8 analog sensors. Multiple VT408 units can be connected using a daisy CAN chain. Sensors connected to the extension unit appear in the system automatically.

Systems with analog ports:

To read data from the analog sensors, you need Vutlan monitoring and control system. All the following monitoring & control systems have a different amount of analog ports.